Core Control Technology

Industry first

Compatibility

The system is perfectly compatible with the CNC machine tool systems of Fanuc, Mitsubishi, Siemens, Brother and Beijing Jingdiao etc. With no external device and subject to no point restriction, it can communicate with the machines directly to realize rotation at any angle, and backlash and single angle compensation, thus improving the machining precision.

Fanuc

Mitsubishi

Siemens

Brother

Jingdiao

Advantages of UCS Controlling System

Disadvantages of Convantional I/O Control

4th or 5th axis rotary table is controllal by direct order, the angle and speed are optionally specified.

Not limited by machine control system and the 4th axis permissions. No need to change machine internal parameters, it’s directly installed, convenient and faster.

Communicate with machine to achieve closed-loop control,faster and safer.

Angle compensation function is realized by using the probe.

I/O signal is unstable and vulnerable to interference from external signals,resulting in risk.

There are limited number of machine I/O ports, and it is impassible to achieve more angle control. Changing the machine ladder diagram can easily cause the machine to unstable status.

It is impossible to realize angle compensation function after probe measurement.

The control mode is not flexible enough.

In order to achieve universal control in traditional I/O mode, it is necessary to set the angle triggered by I/O signal in advance to perform 4th or 5th axis functions; various composite angles and I/O combinations can easily lead to the risk of mis-remembering. When switching parts, it is necessary to manually adjust the setting angle of backstage, which is heavy workload and cumbersome.

In order to achieve universal control in traditional I/O mode, it is necessary to set the angle triggered by I/O signal in advance to perform 4th or 5th axis functions; various composite angles and I/O combinations can easily lead to the risk of mis-remembering. When switching parts, it is necessary to manually adjust the setting angle of backstage, which is heavy workload and cumbersome.

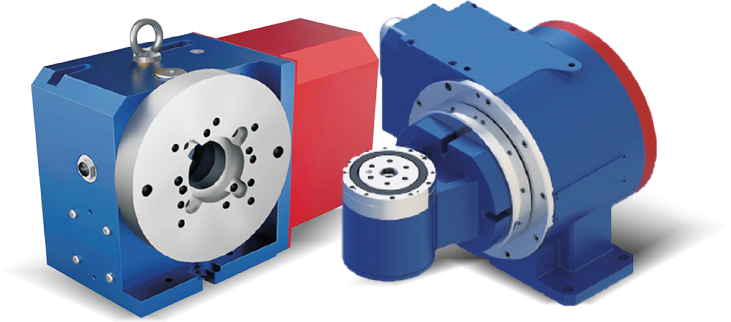

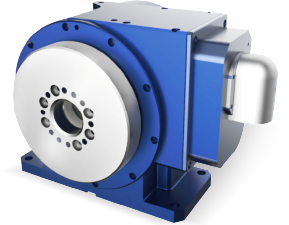

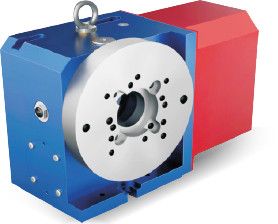

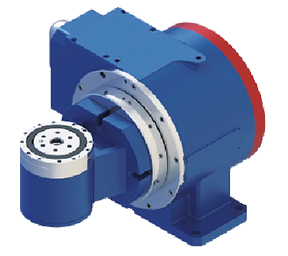

Product series

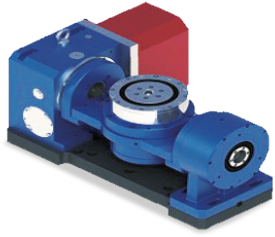

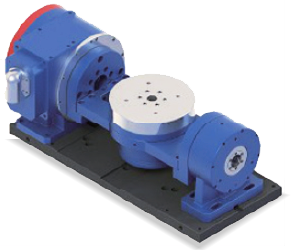

4 th Axis Rotary Table Series

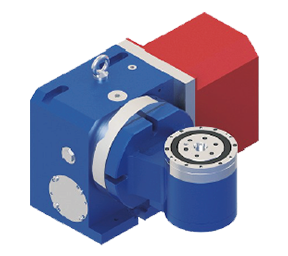

C Axis Rotary Table Series

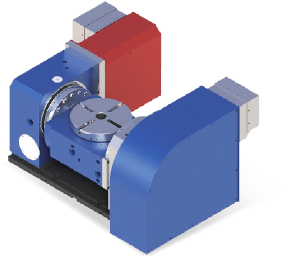

5th Axis Rotary Table Series

Product series

Product series